- Tongwei Solar is planning a vertically integrated capacity expansion from polysilicon to PV module for the upcoming terawatt PV market

- While TOPCon is the mainstream cell technology for the company as of now, Tongwei continuing its development with HJT

- At the module level, Tongwei offers products based on PERC, TOPCon and HJT, with various sizes and shapes to suit a variety of applications

The vertical integration trend in PV manufacturing is gaining momentum. Manufacturers are seeking greater control over quality, costs, and supply chain resilience in the face of fluctuating market conditions.

At first glance, it’s evident that several cell-only manufacturers have successfully ventured into the module business. Tongwei Solar is a very relevant company in this context. The world’s largest cell maker has begun selling modules under its own brand. Beyond cells, Tongwei is also a leading silicon producer, and the company has expanded its operations to include ingot and wafer production, effectively covering every link in the value chain, albeit with varying levels of capacity and integration at each stage.

This was also the theme of the presentation from Jason Xia, Director of PV Module R&D Department of Tongwei Solar, at the TaiyangNews High-Efficiency Solar Technologies 2023 Conference. In addition to discussing Tongwei’s capacity building, Xia also presented the company’s latest product portfolio.

Aggressive expansion

Tongwei Solar is undergoing a significant vertical integration push. In 2021, the company initiated its strategy for vertical integration, starting with an in-house supply chain that spans from polysilicon to ingots, wafers, and modules. By 2023, the company had expanded its polysilicon production capacity from an initial 180,000 tons per annum to 420,000 tons and has set a goal to reach 1 million tons annually within the next few years. Additionally, its current annual capacity of 15 GW for ingots and wafers is projected to increase to over 47 GW. Tongwei Solar’s cell production capacity, currently at 90 GW, is expected to rise to 150 GW by the following year, according to Xia. At the module level, the company’s annual capacity of 55 GW is set to expand to more than 100 GW.

To support this growth strategy, Tongwei Solar has invested heavily in R&D. The R&D resources of the company include facilities across 2 locations – Chengdu, Sichuan Province, and Anhui Province – over 600 researchers covering various PV technology fields and a patent portfolio of 1,822 by the end of Q3 2023.

Cell development

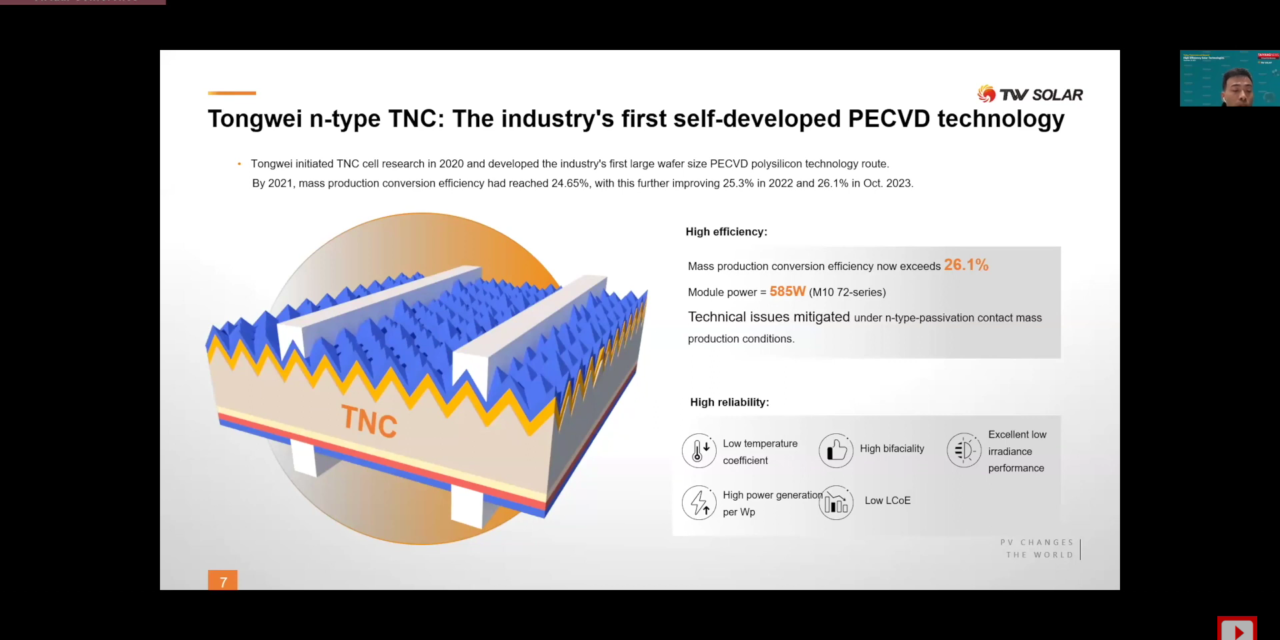

While TOPCon remains the mainstream cell technology, Tongwei Solar is also advancing its development with HJT. For TOPCon, the company embarked on its development journey in 2020, choosing the PECVD method to execute all the 3 critical steps of rear surface engineering. This process involves applying a tunneling oxide layer, a thin polysilicon layer, and in-situ doping – all achieved through a novel tube-type PECVD tool it co-developed with Leadmicro and Nantong University, according to Xia. Beyond rear surface engineering, Tongwei incorporates selective emitter (SE) technology to create emitters with high sheet resistance, improving cell performance as a result. Highlighting the company’s achievements with TOPCon, Xia emphasized that 24.65% mass production efficiency was reached with cells based on M10 wafers by 2021, which was further improved to 25.3% in 2022 followed by 26.1% by October 2023. Tongwei calls its TOPCon technology as TNC.

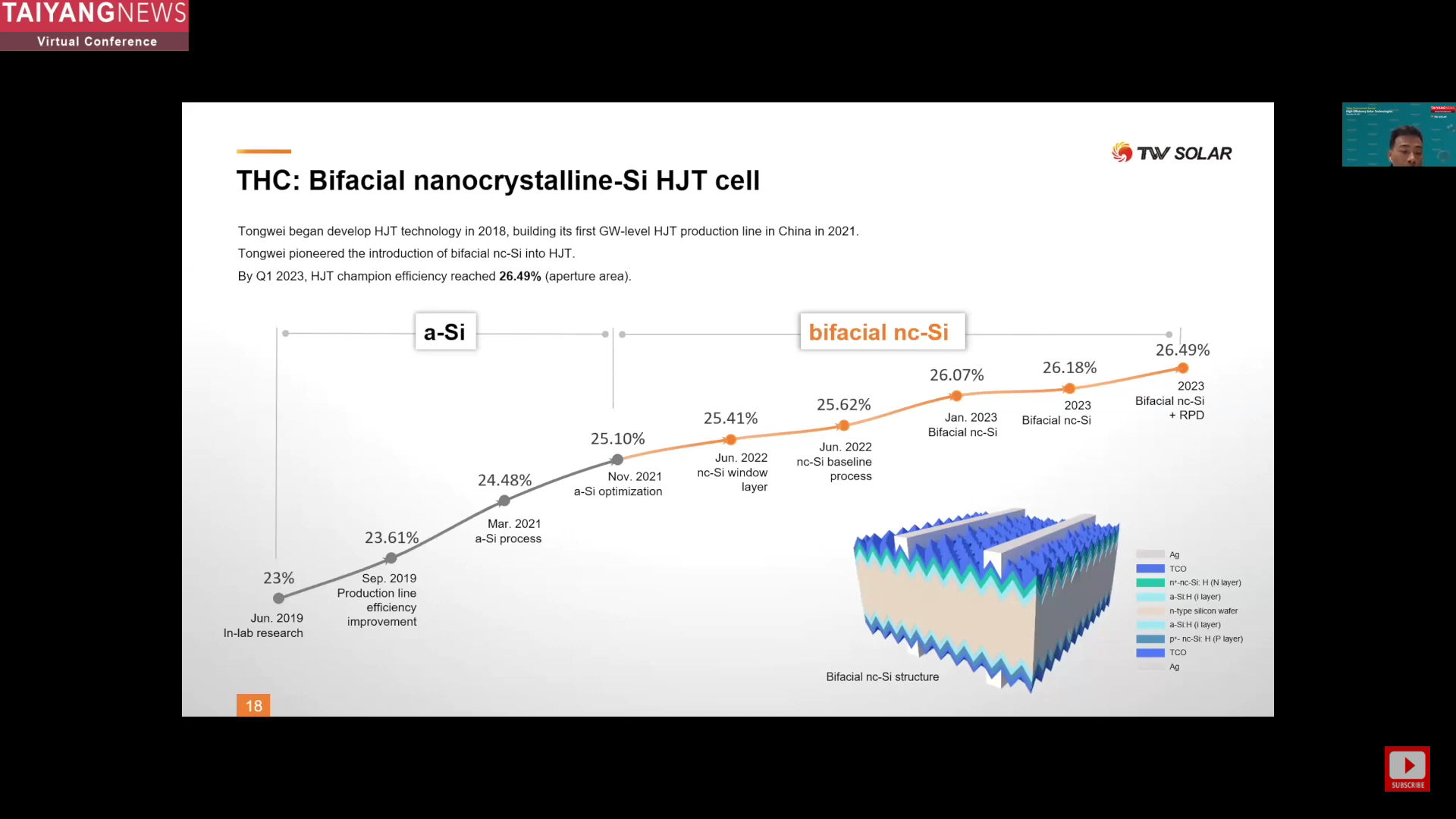

Progress at a glance: Tongwei’s series of advancements, including the innovative application of doped nano-crystalline silicon on both sides, has culminated in achieving an impressive 26.49% efficiency, as illustrated above. (Photo Credit: TaiyangNews)

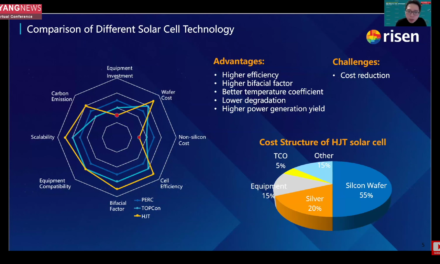

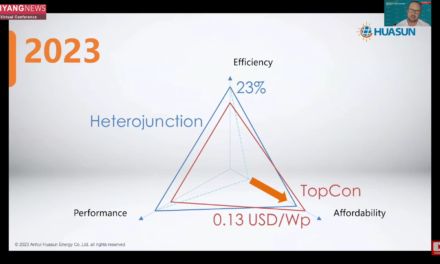

Tongwei is one of the early adopters of HJT technology on a commercial scale, with the installation of a GW-scale production facility initiated in 2021, building upon R&D activities that had already commenced in 2018. According to Xia, Tongwei played a leading role in introducing a bifacial nano-crystalline silicon layer into the HJT cell structure. Furthermore, the company built a pilot line to develop silver-free copper metallization technology that enabled it to thin down the contact fingers to less than 15 µm, enhancing cell efficiency by 0.2% compared to the traditional screen-printing process. By Q1 2023, the champion cell efficiency of its HJT technology reached 26.49%. Tongwei Solar has named its high-efficiency HJT cell ‘THC.’

Product portfolio

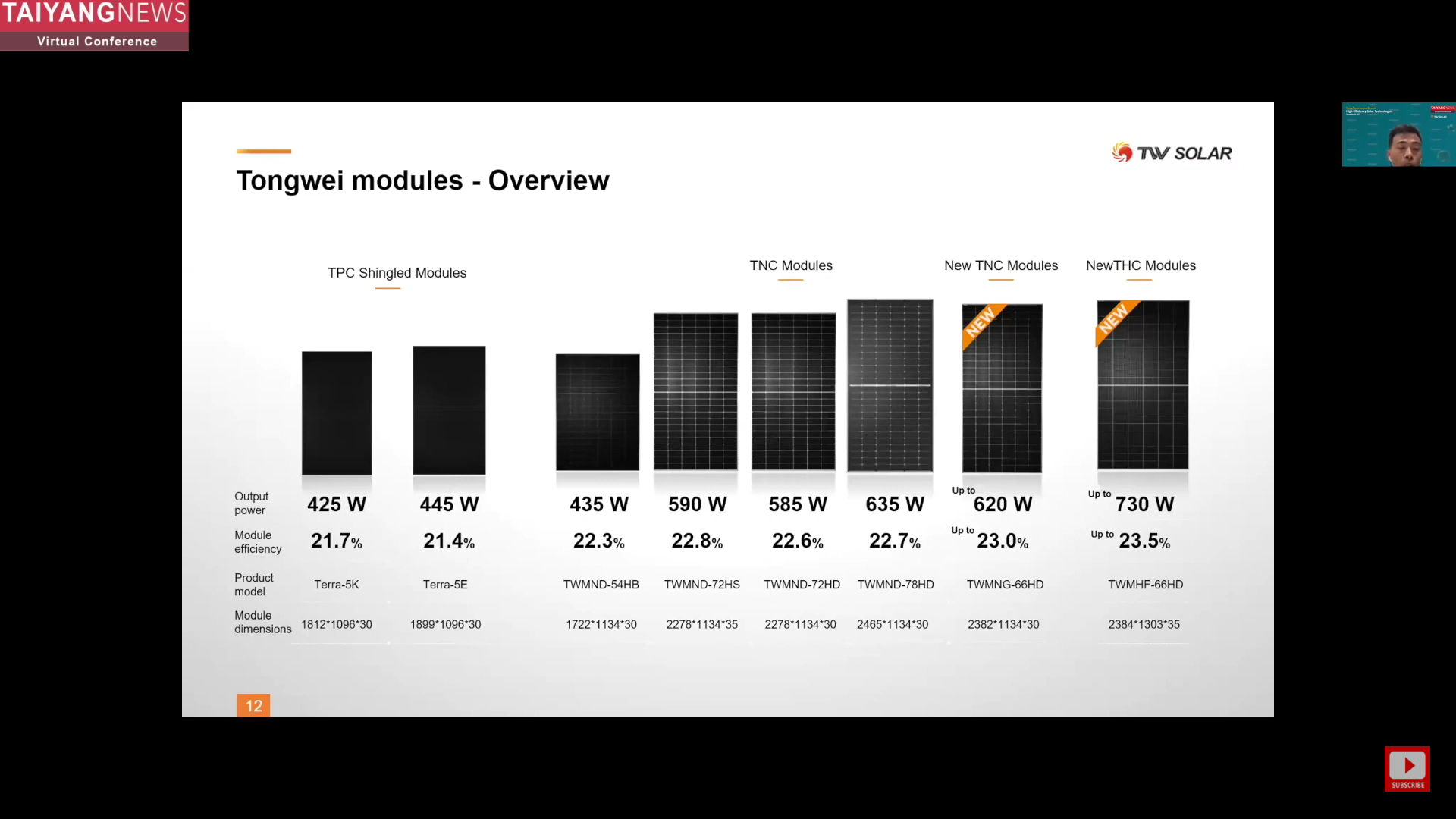

Based on its proprietary cell technologies, Tongwei Solar offers a diverse portfolio of modules. Among these are the TPC Shingled modules based on PERC, tailored for residential rooftop applications. The Chinese manufacturer offers 2 models utilizing the shingling technology: the Terra-5K and Terra-5E. These models boast power ranges between 425 W and 445 W, with efficiencies of 21.7% and 21.4%, respectively. In its TNC module lineup, the company’s TOPCon product brand, the 26.1% efficient TNC cell enables a module rated power of 585 W to 590 W. These modules are based on the M10 cell size in a 72-cell configuration, designed for utility and C&I applications. The series consists of 2 models: the TWMND-72HS with an efficiency of 22.8%, and TWMND-72HD with 22.6%. In addition, the company recently introduced a new TOPCon module based on the M12R size cell, which has a power rating of up to 620 W and an efficiency of 23%, designed for the utility segment.

Regarding HJT modules, the company has launched its first M12 size ultra-thin wafer bifacial nano-crystalline THC module. This TWMHF-66HD module has a power rating of up to 730 W and an efficiency of 23.5%. The products also feature advanced silver-free metallization technology and zero-busbar (0BB) interconnection technology, which collectively improves performance and reliability while reducing costs. Tongwei Solar plans to begin mass production of these latest HJT module series to be based on M12 or M12R sized cells in Q1 2024.

In-house innovation: Tongwei, in collaboration with its partners, claims to be the first to develop PECVD technology capable of completing all deposition steps for rear surface engineering with TOPCon. (Photo Credit: TaiyangNews)