Expanding Frontiers – Capacities And Technologies

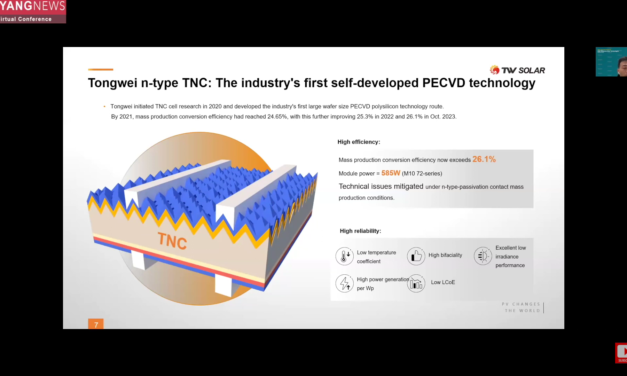

Tongwei, In Addition To Capacity Building All Along The Value Chain, Is Also Diversifying With Cell Technologies

Friday, 29 Mar 2024

The vertical integration trend in PV manufacturing is gaining momentum. Manufacturers are seeking greater control over quality, costs, and supply chain resilience in the face of fluctuating market conditions.

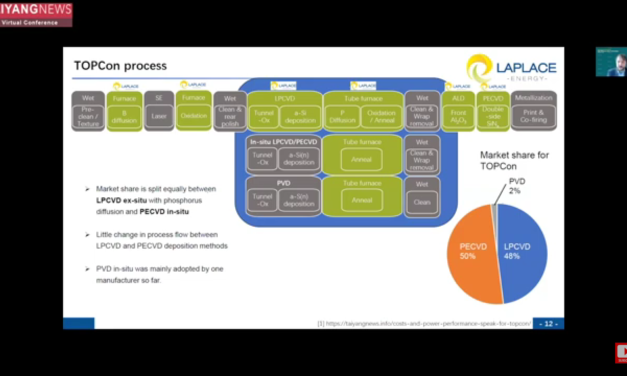

LPCVD Route For TOPCon

Laplace Presented Its Production Solutions For TOPCon Based On LPCVD And Horizontal Thermal Processing Tools

Friday, 15 Mar 2024

TOPCon, which is the talk of the solar town, is all about the rear surface engineering of an n-type base wafer, essentially applying an optimal passivation scheme.

SiNx Deposition Systems For Silicon Nitride Deposition

Deposition Tools For Silicon Nitride Film Application In Semiconductor And Solar Cell Manufacturing

Thursday, 21 Sep 2023

The PECVD tools promoted for aluminum oxide deposition are not too different to the ones used for silicon nitride. In fact, the former tools were derived from the latter by changing the precursor supply system and cleaning mechanism.

PECVD Systems For Aluminum Oxide Deposition

PECVD Systems Streamline Alox Deposition By Adding A Sinx Capping Layer Within A Single Vacuum, Optimizing PERC Solar Cell Rear Passivation

Tuesday, 19 Sep 2023

TaiyangNews recent market survey on cell production survey features tools from various equipment suppliers; in our previous article published on this topic we provided details for ALD Systems For Aluminum Oxide Deposition.

HJT Processing: Shifting To Micro Silicon Layers

The Introduction Of A Microcrystalline Silicon Layer Into The HJT Structure Is The Key Development In The Core Layer Deposition Step

Monday, 24 Apr 2023

When wafers enter the core layer deposition stage, it means they reach the heart of HJT processing. This stop follows wet etching, which we discussed in a separate article (see Cleaning Has Big Role In HJT).

Semco Smartech Speaks on Current TOPCon Cell Manufacturing Trends

Semco Smartech CEO Raymond De Munnik Presented Manufacturing Trends and Cost Comparisons for TOPCon cells

Wednesday, 25 Jan 2023

During the TaiyangNews Virtual Conference on High Efficiency Solar Technologies 2022 – TOPCon, HJT and Beyond, Today & Tomorrow, Raymond De Munnik, CEO SEMCO Smartech emphasized that TOPCon is a mature technology already in 2022, with a ‘big cell line installation boom’ going on.

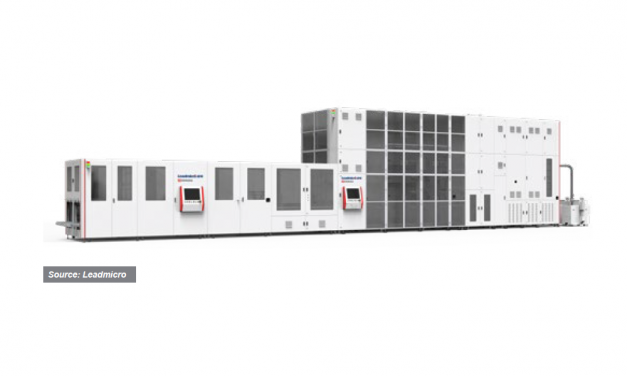

PECVD Based Solution For Polysilicon in TOPCon Cells

Video: Boachen Liao From China’s Lead Micro Talks About PECVD Based Solution For Polysilicon Layer In TOPCon Mass Production at TaiyangNews Event

Monday, 16 Jan 2023

During the TaiyangNews Virtual Conference on High Efficiency Solar Technologies 2022 – TOPCon, HJT and Beyond, Today & Tomorrow, Lead Micro’s Chief Scientist, Prof. Boachen Liao represented the equipment production side at the event.

The Supply Side Of PECVD Tools For HJT – Part 2

While Our Previous HJT PECVD Article Covered Tool Suppliers Manly From China, There Are Few More, And Also Offering Other Technologies

Monday, 17 Oct 2022

This is the second part on PECVD production equipment suppliers for HJT solar cell processing, which follows on article published last week that covered Chinese suppliers (see The Supply Side Of PECVD Tools For HJT – Part 1).

One Coat, Two Functions

Balancing Between Passivation And Optical Properties Is The Key For PECVD SiNx Deposition Tools

Wednesday, 14 Sep 2022

PECVD tools have been the work horse for application silicon nitride film applied on the emitter of the p-type solar cells since the past BSF days to the current PERC.

Two-In-One With PECVD

PECVD Come With An Inherent Advantage Of Depositing Aluminium Oxide On Solar Cells As Well As The Capping Silicon Nitride In One Go

Tuesday, 06 Sep 2022

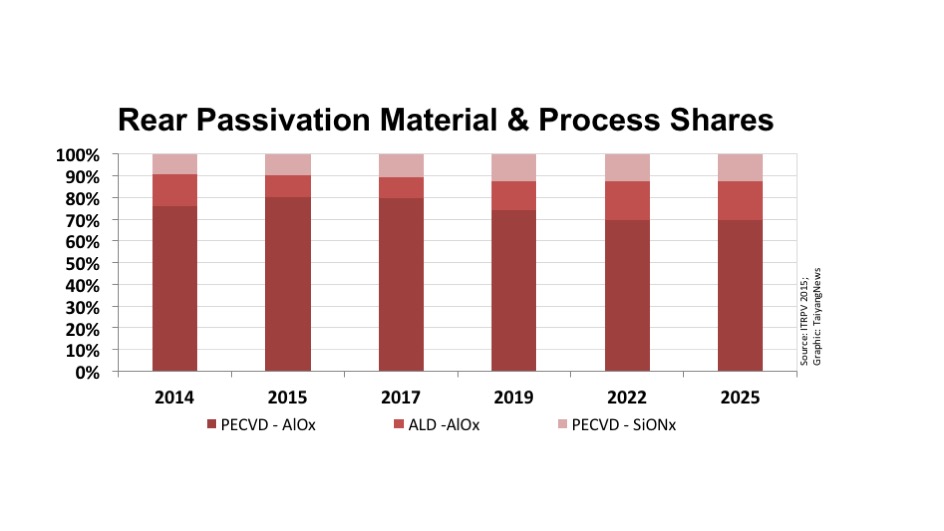

As part of our PERC Solar Cell Production 2022 report, we also looked into passivation tools. PECVD is one of the two mainstream methods employed to deposit aluminium oxide used as the rear passivation dielectric in PERC structure.

No Wrap-Around With PECVD

Several PV Equipment Makers Working on PECVD Tools For TOPCon Solar Cell Production

Wednesday, 02 Mar 2022

Addressing the shortcomings of LPCVD equipment for the production of TOPCon solar cells, as discussed in our earlier article (see LPCVD for TOPCon Cells), especially the wraparound, the PV industry is increasingly getting interested in PECVD technology.

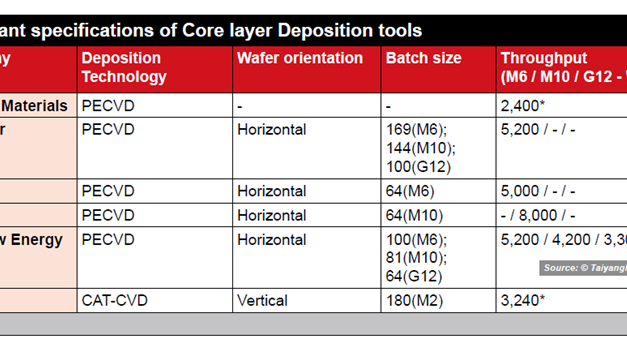

Suppliers Of Core Layer Deposition Tools For HJT

While One Leading PECVD Supplier Exited From The Open Market, Several Chinese Companies Are Foraying Into Core Layer Deposition Tools For HJT Solar Cells

Sunday, 07 Feb 2021

PECVD is more or less the current state of the art in the regular equipment stream for core layer deposition of heterojunction (HJT) solar cells.

The Core Of HJT

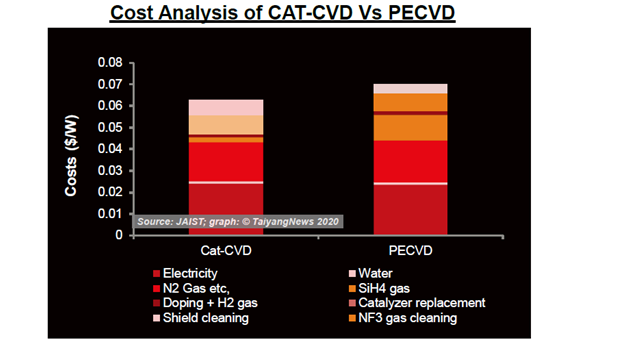

While PECVD Is The Widely Followed Technology For Applying Core Layer In HJT, CAT-CVD Was Also In Use And PEALD Is In Development

Tuesday, 19 Jan 2021

Core layer depositions the heart of HJT processing. It involves multi-layer stacking of intrinsic-amorphous and doped-amorphous silicon layers of opposite polarities on each side of the wafer and controlling them at the nanometer scale.

How Much to Put Down the Rear Deposit On PERC Cells?

Thickness Of Aluminum Oxide Film And Precursor TMA Consumption Varies As Per Deposition Technology & Changes With Equipment

Monday, 11 May 2020

The two mainstream manufacturing technologies that are currently available for application of the rear passivation stack of PERC cells are ALD and PECVD. In fact, the method of deposition affects the thickness of the deposition.

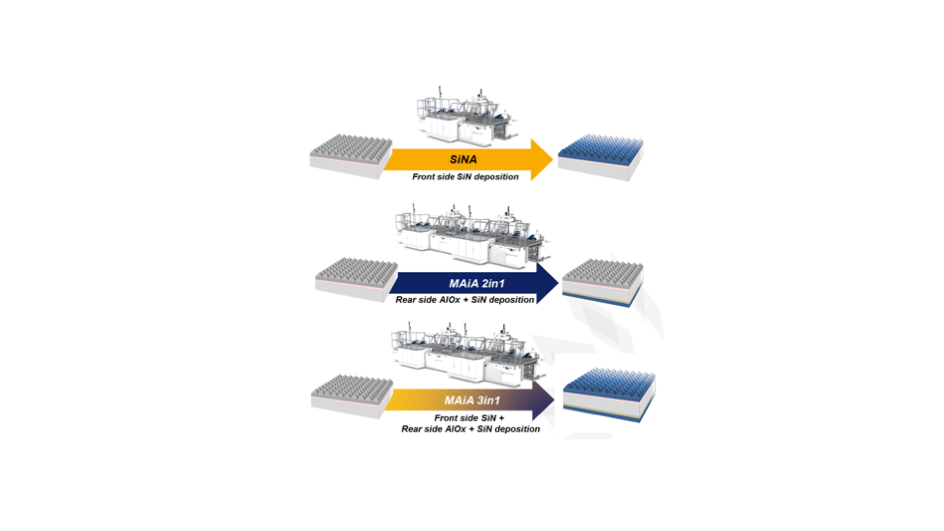

Universal PERC Tool From Meyer Burger

Swiss PV Production Equipment Maker Introduces Platform To Address All Passivation Needs Of PERC Cell Lines With One Tool

Wednesday, 01 Feb 2017

As part of PERC processing, Plasma Enhanced Chemical Vapor Deposition (PECVD) has an undeniable advantage of depositing aluminum oxide and silicon nitride capping layer simultaneously in one system.

Subscribe To Newsletter

Latest Videos

Most Popular

#China Solar PV News Snippets: Drinda's Q1 solar cell shipments surge; CECEP Solar to raise RMB 2.95B; @JASolarOfficial postpones HJT pilot plant; @ChinaSPIC initiates over 72 GW ...of clean energy projects; China Huaneng building 850 MW offshore PV project https://taiyangnews.info/china-solar-pv-news-snippets-238/

Italian solar energy association @italia_solare has warned that the government’s decision to ban ground mounted PV installations on agricultural sites will lead to a loss of ...around €60 billion & jeopardize #Italy's 2030 solar targets #solarenergy #SOLAR https://taiyangnews.info/italian-solar-industry-concerned-blocking-agricultural-land-use-italia-solare/

Independent energy company energyRe has secured $240 million in financing and tax equity commitments for its 108 MW DC Lone Star Solar Project with 198 MWh storage, calling it one... of the largest solar and storage facilities in the southeastern US #solarpv https://taiyangnews.info/energyre-240-million-financing-equity-commitment-us-project/

Renewable energy company @AmeaPower signs long-term PPA for its 120 MW Doornhoek Solar PV Project in #SouthAfrica with national utility @Eskom_SA, marking its entry into the ...African nation. The project was one among 5 selected under REIPPPP bid window 6 https://taiyangnews.info/amea-power-secures-south-african-power-purchase-agreement/

Panelists on #day2 of @TaiyangNews Virtual Conference on #PVProductionEquipment were unanimous in their view that local solar module production is definitely achievable, but need ...to find market, demand & offtakers first to ensure success #solarenergy #solarpv #RenewableEnergy

- JinkoSolar Delivers More than 1.1 Million Tiger Neo Modules to One of The Largest PV Projects in Germany and Europe

- Only 4 Steps! Witness the Birth of a Huasun Heterojunction Solar Cell

- DAH Solar Full-Screen Colored PV Module, The Most Beautiful Choice of BIPV

- Hopewind signed an agreement with MAIROTEC Energy to deploy innovative agri-pv applications in Germany with HEIDE SOLAR

- Huasun Wins Customer Innovation Award from H.B. Fuller for Its Pioneering Application in Solar Industry